PACKEY PACKING MATERIAL(JIANGSU) CO.,LTD

VCI Gas phase anti-rust aluminum foil film/aluminum foil anti-rust film/aluminum foil composite film/Aluminum foil composite anti-rust film/Aluminum plastic composite anti-rust film/Gas phase aluminum foil film /VCI aluminum foil film /VCI gas phase anti-rust anti-static shielding moisture-proof aluminum foil packaging film/bag details:

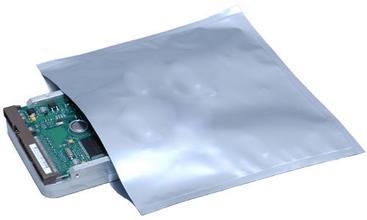

Summarize:VCI gas phase anti-rust aluminum foil film/aluminum foil anti-rust film/aluminum foil composite film/Aluminum foil composite anti-rust film/Aluminum foil composite anti-rust film/gas phase aluminum foil film /VCI aluminum foil film /VCI gas phase anti-rust anti-static shielding moisture proof aluminum foil packaging film/bag is our research personnel in VCI gas phase anti-rust plastic film and anti-static shielding moisture proof aluminum foil film On the basis of foil film, comprehensive high-tech gas phase rust prevention technology, plastic extrusion and blow molding technology, anti-static technology and moisture-proof technology, using special processing technology composite production. It integrates air, water vapor, corrosive gas, dust, sunlight barrier required by vacuum dry packaging, vapor phase rust prevention required by anti-static packaging, anti-static shielding required by anti-static packaging and physical strength required by packaging function. It has excellent anti-corrosion, strength and anti-static shielding function, which can protect mechanical parts. In particular, electronic products are not damaged by rust, moisture and static electricity, Especially suitable for integrated circuit boards, printed circuit boards, communication equipment, electronic instruments and meters and all kinds of machine tools, large military equipment, textile equipment, printing and packaging equipment, rubber and plastic processing equipment, compressors, engines and other large mechanical and electrical equipment and components such as rust and moisture and anti-static shielding products and materials during the process or storage, shipping packaging. This product can also be made into a bag, the electronic products into the bag can be sealed. The internal and external surface resistance reaches 10⁸~1010Ω.

1、Brand:PACKEY Model number:PK -A126(Polymetallic universal type)

2、Product specification type introduction:

Specification: The width is less than 1600mm, the common width is 1000mm, roll material or sheet material, can be heat sealed

3、Introduction of working mechanism:Reinforced aluminum-plastic composite VCI gas phase anti-rust anti-static shielding moisture-proof aluminum foil packaging film/bag is based on VCI gas phase anti-rust plastic film and anti-static shielding moisture-proof aluminum foil film, integrated high-tech gas phase anti-rust technology, plastic extrusion and blow molding technology, anti-static technology and moisture-proof technology, using special processing technology composite production. It integrates air, water vapor, corrosive gas, dust, sunlight barrier required by vacuum dry packaging, vapor phase rust prevention required by anti-static packaging, anti-static shielding required by anti-static packaging and physical strength required by packaging function. It has excellent anti-corrosion, strength and anti-static shielding function, which can protect mechanical parts. In particular, electronic products are not damaged by rust, moisture and static electricity, Especially suitable for integrated circuit boards, printed circuit boards, communication equipment, electronic instruments and meters and all kinds of machine tools, large military equipment, textile equipment, printing and packaging equipment, rubber and plastic processing equipment, compressors, engines and other large mechanical and electrical equipment and components such as rust and moisture and anti-static shielding products and materials during the process or storage, shipping packaging. This product can also be made into a bag, the electronic products into the bag can be sealed. The internal and external surface resistance reaches 10⁸~1010Ω.

4、Advantages/features introduction:

A, with excellent anti-rust performance, anti-rust period can reach more than one year, and the barrier gas release quickly, 2 hours can be allowed to fill all corners of the package;

5、Application field introduction:

Automotive field: car body, engine, flywheel, brake disc and various steel parts.

Electronic appliances: control board, computer, motor, communication equipment, electronic parts, etc.

Precision machinery: precision mold, precision machinery, watch parts, etc.

Heavy machinery: all kinds of large machinery, agricultural machinery, transportation machinery, boiler machinery, etc.

Marine, aviation: engines, engines, motors, turbine parts, etc.

Other: bearing, hand tools, drill, power tools, etc.

6、Applied metal:

■ Rust prevention for ferrous metal: applicable to cast iron, carbon steel, silicon steel and other ferrous metal products

■ Multi-metal rust prevention: suitable for alloy products composed of various metals, such as steel, copper, aluminum, zinc, etc

■ Copper anti-rust: suitable for copper and copper alloy products

■ Precious metal special rust prevention: suitable for gold plated, silver plated precious metal products

7、Precautions for use:

A. The product must be sealed and packaged;

B. The product must be clean and rust free before packaging;

C. Wear gloves when packing products to avoid direct contact between hands and parts;

D. Take into account whether the product has undergone other chemical treatments before packaging;

E. Packaging products should not exceed 60 degrees Celsius, preferably cooled to room temperature;

F. Avoid outdoor work, avoid direct sunlight, pay attention to moisture and rain and fog weather;

G. If the volume of the packaged material is too large or the surface area of the product to be protected is too large, auxiliary agents need to be added;

H. For unused anti-rust products, seal them in time.

8、Product storage: sealed storage in a dry, cool place, avoid contact with chemicals, avoid direct sunlight.

9、Shelf life: 12 months from the date of delivery

Rust prevention period of more than one year

Rust prevention capability through third-party testing and international SGS and REACH certification. Fully meet export requirements.

Scan it

Scan it