PACKEY PACKING MATERIAL(JIANGSU) CO.,LTD

The VCI vapor phase anti-rust masterbatch /VCI resin produced by PACKEY Packaging Materials (Jiangsu) Co., Ltd. is introduced in detail:

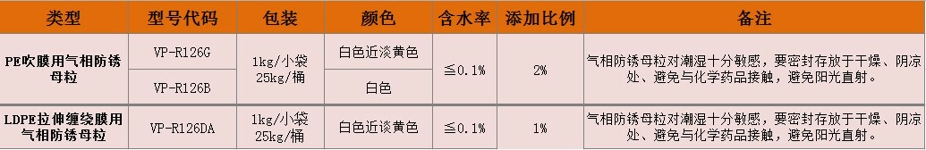

Summarize:VCI vapor anti-rust masterbatch /VCI resin produced byPACKEY Packaging Materials (Jiangsu) Co., Ltd. is a VCI vapor anti-rust additive specially developed by our company for the production of VCI vapor anti-rust film and VCI vapor anti-rust stretch winding film. It is composed of a variety of vapor corrosion inhibitors and a variety of additives by special process. The masterbatch is pale yellow or white. The gas phase rust prevention masterbatch is mixed in LDPE and LLDPE plastic particles in the prescribed proportion, so that the gas phase rust prevention agent is fully dispersed, and the gas phase rust prevention film is made by blowing film unit or the gas phase rust prevention stretch winding film is made by casting unit. In the production process, the heating temperature of each area of the film blowing machine can not exceed 190 ° C. Under normal circumstances, the addition ratio is shown in the table above, and various PE color masterbatches can also be added as needed.

1、Brand:PACKEY Model number:PK -A125(Polymetallic universal type)

2、Functional mechanism introduction:The characteristics of the gas phase anti-rust masterbatch is added to the plastic products, at normal temperature and pressure can volatilize a gas, the gas is adsorbed in the form of molecules on the protected metal surface, isolate the contact between the air and the metal to achieve the anti-rust function, uniform dispersion, no crystal point, safe and non-toxic, long anti-rust period. The anti-rust period is 2 years, up to 5 years according to the situation. This series masterbatch (material) can add other functions on the anti-rust function according to customer requirements: anti-static, opening, smoothness, transparency, etc.

3、Advantages/features introduction:

A, no nitrite;

4、Application field introduction:

Automotive field: car body, engine, flywheel, brake disc and various steel parts.

Electronic appliances: control board, computer, motor, communication equipment, electronic parts, etc.

Precision machinery: precision mold, precision machinery, watch parts, etc.

Heavy machinery: all kinds of large machinery, agricultural machinery, transportation machinery, boiler machinery, etc.

Marine, aviation: engines, engines, motors, turbine parts, etc.

Other: bearing, hand tools, drill, power tools, etc.

5、Applied metal:

Steel, cast iron, cadmium and alloy, stainless steel, electroplated metal, chromium and alloy, tin and alloy, zinc alloy, nickel alloy, copper and copper alloy, etc

6、Precautions for use:

A. The addition ratio of the product is 1:50;

B. The mixture of gas phase rust prevention masterbatch and PE raw materials should be uniform;

C. Pay attention to temperature control when blowing gas phase anti-rust film;

D. Pay attention to moisture-proof and rain and fog weather when blowing gas phase anti-rust film;

E. The color of the anti-rust film can be added according to customer requirements. The color masterbatch not recommended by our company will affect the anti-rust effect;

F. For the gas phase rust prevention masterbatch that has not been used, it should be sealed and kept in time, and pay attention to moisture.

7、Product storage: The gas phase anti-rust masterbatch is very sensitive to moisture, and should be sealed and stored in a dry and cool place to avoid contact with chemicals and direct sunlight.

8、Shelf life: 12 months from the date of delivery

Rust prevention capability through third-party testing and international SGS and REACH certification. Fully meet export requirements.

Scan it

Scan it